PTFE-POLYTETRAFLUOROETHYLENE

PTFE is a highly crystalline, thermoplastic, highly advanced polymer for very demanding applications. Fluoroplastics is the collective name for a number of plastics containing flourine. PTFE is available blended with glass to improve form stability and wear resistance. These include PTFE, PVF, PVDF, PCTFE, ECTFE etc.

Chemical designation:

Polytetrafluoroethylene

Abbreviation:

PTFE

Natural colour, additives:

White, opaque

Supplied as:

• Round rod

• Sheets

• Hollow bars

• Film, hose, O-rings, profiles etc.

• End products, machined or cast

Principal properties:

• High temperature resistance

• Tough at low temperatures. (down to -160 °C)

• Very low friction coefficient

• Excellent resistance to chemicals

• Low water absorption

• Not attacked by microorganisms

• High density

• Resistant to hydrolysis, including in superheated steam

• Excellent electrical and dialectical properties

• Not abrasion resistant

Applications:

Machine and vehicle production, transport and feeding technology, electrical engineering, precision engineering, food technology, medical technology and chemical technology.

Machine and vehicle production, transport and feeding technology, electrical engineering, precision engineering, food technology, medical technology and chemical technology.

Examples of use:

• Slide bearings

• Electrical components for aircraft/robots

• Slide rails

• Pipes

• Seals

• Machine components

• Insulating material

• Gaskets

• Coatings (cooking pots etc.)

• Filters

machined detail

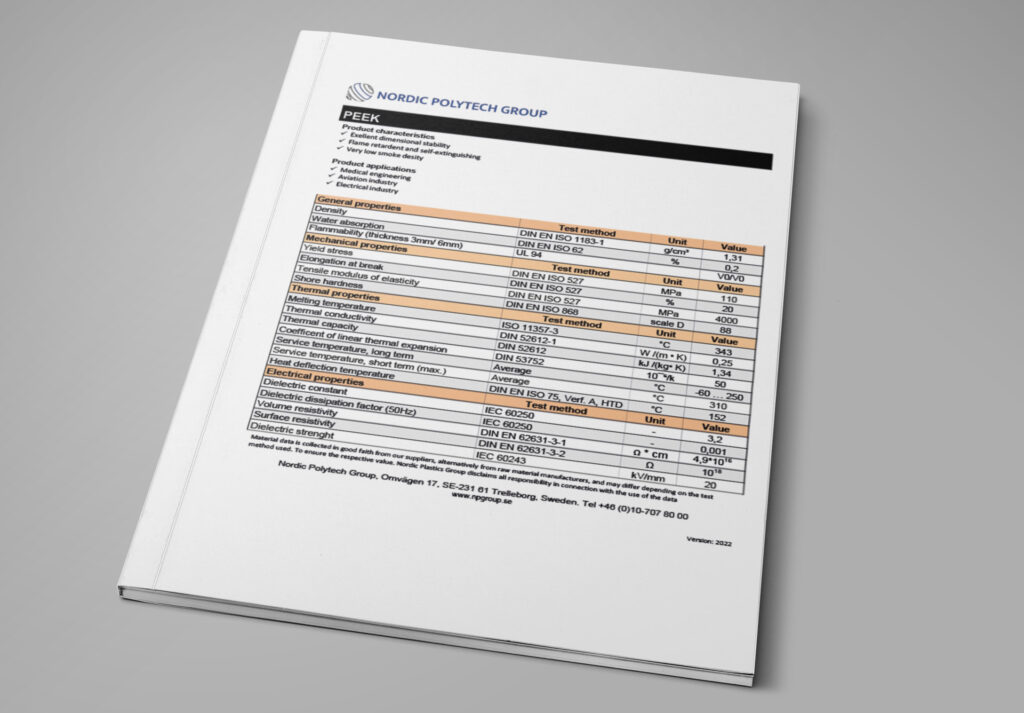

Technical information

/Product sheet